When it comes to the history of plumbing, PEX has certainly made its mark. This modern plumbing innovation has revolutionized the industry with its flexibility and durability. But have you ever wondered when PEX plumbing first came into existence?

Polyethylene cross-linked (PEX) plumbing pipes were first introduced in the United States in the early 1980s. Developed as an alternative to traditional copper and PVC pipes, PEX quickly gained popularity due to its ease of installation and resistance to freezing temperatures. Today, it has become a go-to choice for residential and commercial plumbing systems.

Pex plumbing, also known as cross-linked polyethylene plumbing, first emerged in the 1960s. It gained popularity in the United States during the 1980s due to its ease of installation and resistance to corrosion. Compared to traditional copper and galvanized steel pipes, Pex offers a more flexible and cost-effective plumbing solution. Its durability and versatility make it a preferred choice for residential and commercial plumbing systems. Since its introduction, Pex plumbing has revolutionized the industry and become a widely accepted alternative to traditional plumbing materials.

Introduction: PEX Plumbing Revolutionizes the Industry

When it comes to plumbing systems, PEX (cross-linked polyethylene) is a relatively new innovation that has revolutionized the industry. PEX plumbing offers numerous advantages over traditional materials like copper and PVC, including flexibility, durability, and ease of installation. But when did PEX plumbing actually start? In this article, we will explore the origins of PEX plumbing and its journey to becoming the preferred choice for modern plumbing systems.

The Birth of PEX Plumbing

The development and introduction of PEX plumbing can be traced back to the 1920s when scientists began experimenting with various materials to create flexible pipes. However, it was not until the 1960s that the first commercially successful PEX plumbing system was created.

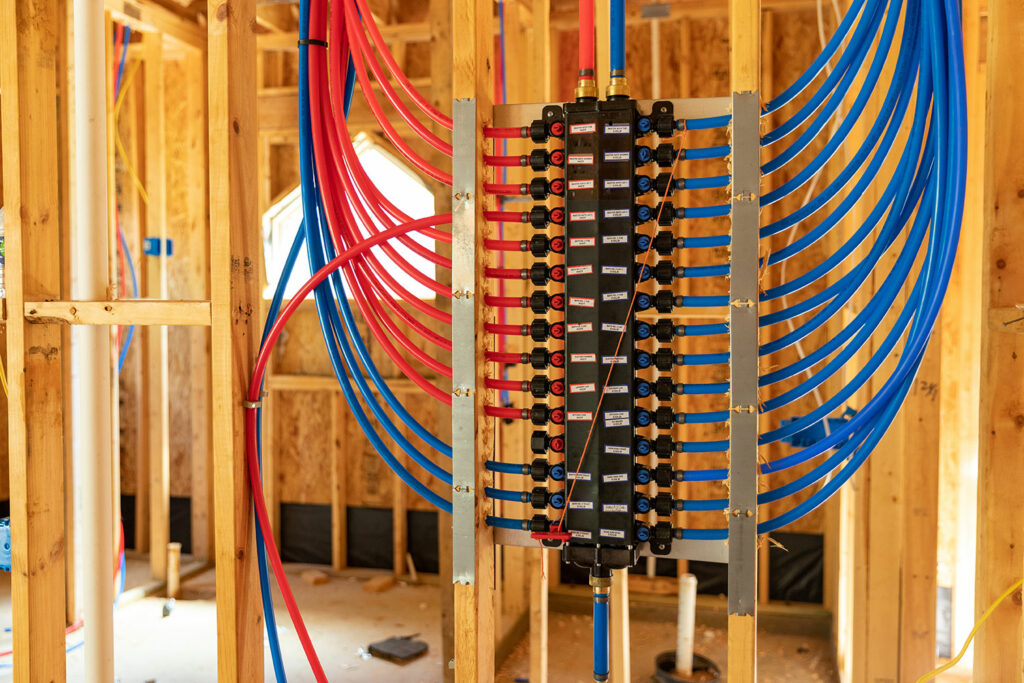

The initial use of PEX pipes was mainly in radiant heating systems, particularly in Europe. PEX gained popularity for its ability to withstand high temperatures and resistance to corrosion. The flexible nature of PEX pipes also made them easy to install, reducing the labor-intensive process of fitting rigid copper or PVC pipes.

Over the following decades, advancements in PEX manufacturing technology further improved the quality and reliability of PEX plumbing systems. This led to increased adoption in a wide range of applications, including residential and commercial plumbing.

Today, PEX plumbing is considered an industry-standard material due to its numerous benefits and widespread use in modern construction projects.

Types of PEX Plumbing Systems

PEX plumbing systems can be categorized into three main types: PEX-A, PEX-B, and PEX-C. Each type has its own manufacturing process and characteristics.

PEX-A Plumbing System

PEX-A, also known as “Engel” or “Perch-A,” is manufactured using the Peroxide method. This type of PEX is known for its high degree of flexibility, allowing it to be bent and shaped without the risk of cracking or breaking. PEX-A pipes are typically more expensive than other types due to the extra manufacturing steps involved.

PEX-A plumbing systems have excellent resistance to freeze damage, making them ideal for cold climates. They can expand up to three times their original diameter without bursting and then return to their original shape once the frozen water thaws.

Additionally, PEX-A pipes have great resistance to chlorine and other chemicals commonly found in water supplies, making them suitable for both potable water and radiant heating systems.

PEX-B Plumbing System

PEX-B, also known as “Silane,” is manufactured using the Silane or Moisture Cure method. It offers moderate flexibility compared to PEX-A and is slightly more affordable.

PEX-B plumbing systems have good resistance to temperature and pressure, making them suitable for both hot and cold water applications. However, they are less resistant to freeze damage compared to PEX-A.

PEX-B pipes are commonly used for both residential and commercial plumbing projects due to their affordability and versatility.

PEX-C Plumbing System

PEX-C, also known as “Electronic Irradiation” or “Peroxide,” is manufactured using the Electronic Irradiation method. It offers the least flexibility among the three types of PEX.

PEX-C plumbing systems have good temperature resistance and can be used for both hot and cold water applications. However, they are more prone to freeze damage compared to PEX-A and PEX-B.

PEX-C pipes are commonly used for radiant heating systems and are less commonly found in residential plumbing applications.

The Rise of PEX Plumbing

PEX plumbing gained significant popularity in North America in the 1980s, mainly due to its ease of installation and cost-effectiveness compared to copper pipes. The flexibility of PEX pipes allowed for simplified installation, reducing the need for fittings and joints.

Furthermore, PEX plumbing systems offered improved resistance to freezing, reducing the risk of burst pipes in colder climates. The durability and longevity of PEX pipes also contributed to their widespread adoption in both residential and commercial applications.

Today, PEX plumbing is commonly used in new construction projects and retrofitting older buildings. Its flexibility, resistance to corrosion, and ease of installation have made it a preferred choice for plumbers and contractors worldwide.

The Future of PEX Plumbing

The adoption of PEX plumbing continues to grow as plumbing professionals recognize its numerous advantages over traditional materials. With ongoing advancements in PEX manufacturing technology and increased awareness of its benefits, PEX plumbing systems are expected to become even more prevalent in the future.

As the demand for sustainable and energy-efficient building practices increases, PEX plumbing will play a vital role in meeting those requirements. Its flexibility, resistance to corrosion, and energy-saving capabilities make it an excellent choice for modern plumbing systems.

As technology and innovation continue to evolve, we can expect further enhancements in PEX plumbing systems, making them even more efficient, durable, and environmentally friendly.

Overall, the advent of PEX plumbing has significantly transformed the industry, enabling cost-effective, efficient, and reliable plumbing systems that meet the demands of modern construction projects.

History of Pex Plumbing

Pex plumbing, also known as cross-linked polyethylene plumbing, revolutionized the plumbing industry with its introduction in the 1960s. It was initially developed in Europe, but gained popularity in the United States in the 1980s.

Prior to Pex plumbing, copper and galvanized steel pipes were commonly used for plumbing systems. However, these materials were prone to corrosion, leaks, and required extensive maintenance. Pex plumbing offered numerous advantages over traditional materials, including flexibility, durability, and resistance to freezing temperatures.

The use of Pex plumbing grew rapidly as more professionals recognized its benefits. It became widely adopted in residential and commercial projects, replacing outdated plumbing materials. Today, Pex plumbing is considered a standard in the industry, with continuous advancements in technology and installation methods.

Overall, the introduction of Pex plumbing in the 1960s revolutionized the plumbing industry by offering a more efficient and reliable alternative to traditional materials. It has become the go-to choice for professionals due to its flexibility, durability, and ease of installation.

Key Takeaways:

- Pex plumbing started gaining popularity in the 1980s as an alternative to traditional copper and PVC pipes.

- The main advantages of Pex plumbing are its flexibility, durability, and resistance to freezing and bursting.

- PEX stands for cross-linked polyethylene, which is a type of plastic used to make the pipes.

- The use of Pex plumbing has increased in recent years due to its ease of installation and lower cost compared to other pipe materials.

- While Pex plumbing is widely used in residential and commercial buildings today, it is important to hire a professional plumber for its installation and maintenance.

Frequently Asked Questions

Pex plumbing is a popular type of plumbing system used in residential and commercial buildings. Here are some frequently asked questions about the history of Pex plumbing.

1. What is Pex plumbing and when did it start?

Pex plumbing is a type of plumbing system that uses cross-linked polyethylene (PEX) pipes. These pipes are flexible, durable, and resistant to corrosion. Pex plumbing first originated in Europe in the 1960s and gained popularity in the United States in the 1980s.

Since its introduction, Pex plumbing has become a widely used alternative to traditional copper and PVC plumbing systems due to its ease of installation, cost-effectiveness, and resistance to freezing. It has revolutionized the plumbing industry and has been widely adopted by professionals and homeowners alike.

2. What are the advantages of using Pex plumbing?

Pex plumbing offers several advantages over traditional plumbing systems. Firstly, Pex pipes are highly flexible, allowing for easy installation in tight spaces and around corners. They are also resistant to corrosion, which extends their lifespan and reduces the need for maintenance or replacement.

Additionally, Pex plumbing is freeze-resistant, making it suitable for both cold and warm climates. This prevents the pipes from bursting during freezing temperatures, reducing the risk of water damage. Pex pipes also have a smooth interior surface, minimizing the buildup of sediment and reducing the chance of clogs.

3. How does Pex plumbing compare to other types of plumbing systems?

Compared to traditional copper pipes, Pex plumbing is much easier and quicker to install. The flexibility of Pex pipes allows for fewer connections, reducing the risk of leaks. Pex plumbing is also more resistant to freezing and corrosion, making it a more durable option.

When compared to PVC pipes, Pex plumbing offers several advantages. Pex pipes are more flexible than PVC pipes, allowing for easier installation. They are also less likely to burst in freezing temperatures, making them suitable for colder climates. Additionally, Pex plumbing is resistant to corrosion, whereas PVC pipes may deteriorate over time.

4. Is Pex plumbing suitable for all applications?

Pex plumbing is suitable for a wide range of applications, including residential and commercial buildings. It can be used for both hot and cold water supply systems, as well as for radiant heating systems. However, there are some restrictions and considerations when using Pex plumbing in certain applications.

For example, Pex plumbing may not be suitable for outdoor applications exposed to direct sunlight, as prolonged exposure to UV rays can degrade the pipes. It is also important to ensure that the Pex pipes are properly sized and installed according to local plumbing codes and regulations.

5. What is the future of Pex plumbing?

Pex plumbing continues to gain popularity in the plumbing industry due to its numerous advantages. Its flexible nature and ease of installation make it a preferred choice for many professionals. As technology advances, we can expect further innovations in Pex plumbing, such as improved materials and installation methods.

Furthermore, Pex plumbing offers a sustainable and environmentally friendly alternative to traditional plumbing systems. Its durability and resistance to corrosion reduce the need for frequent repairs or replacements, leading to less material waste.

#1 PEX Plumbing Mistake You Don’t Want to Make (A vs B)

In conclusion, PEX plumbing started gaining popularity in the United States in the 1980s. It was developed as an alternative to traditional copper and iron pipes due to its flexibility and ease of installation. PEX stands for cross-linked polyethylene, a durable material that can withstand high temperatures and resist corrosion.

The use of PEX plumbing has continued to grow since its introduction, with many homeowners and professionals choosing it for its affordability and reliability. Today, PEX plumbing is widely used in residential and commercial buildings for water supply, heating systems, and other plumbing applications.