Soldering copper plumbing is an essential skill for any professional plumber. With the right technique, it provides a strong and durable connection that ensures leak-free plumbing systems. But did you know that soldering has been used for centuries to join copper pipes? Dating back to ancient times, the art of soldering has evolved to become a cornerstone of modern plumbing.

When it comes to soldering copper plumbing, there are a few key aspects to consider. First, preparation is crucial. Make sure to clean the surfaces that will be soldered and apply flux to ensure a solid bond. Additionally, using a high-quality solder and a suitable heat source is essential for achieving a strong joint. By following these steps, you can ensure that your soldered copper plumbing will stand the test of time, providing reliable water flow and minimizing the risk of leaks.

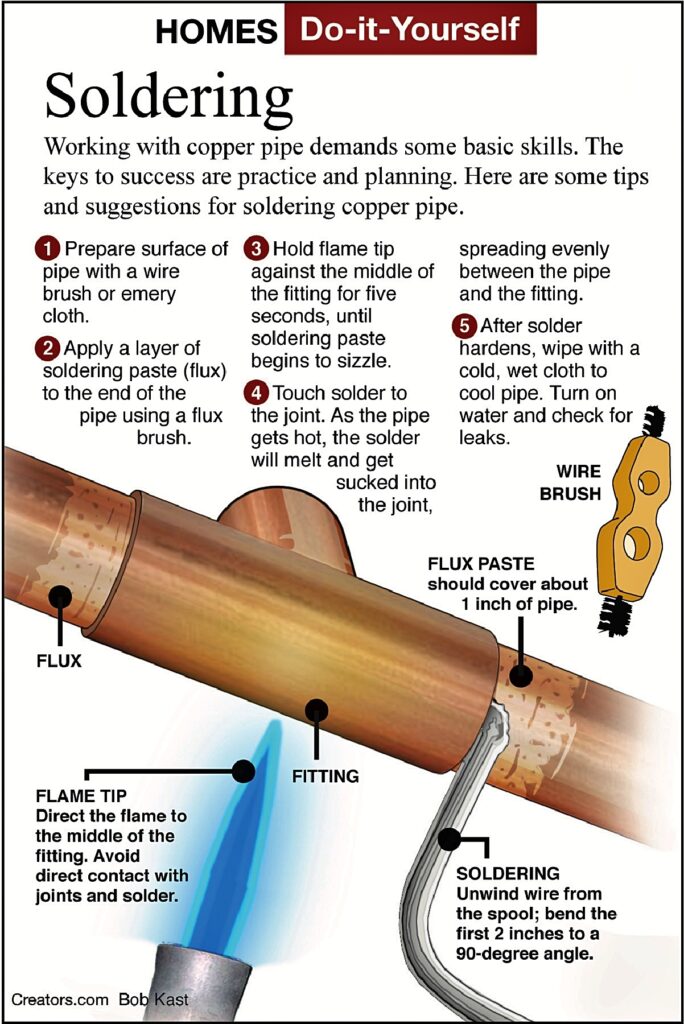

To solder copper plumbing professionally, follow these steps:

- Clean the copper pipes and fittings to remove any dirt or debris.

- Apply flux to the inside of the fittings and the outside of the pipes.

- Fit the pieces together, ensuring they align properly.

- Heat the joint evenly using a propane torch.

- Once the joint is hot enough, apply solder around the joint, allowing it to flow and create a seal.

- Let the joint cool and wipe away any excess solder.

Always remember to practice safety precautions when soldering.

Understanding the Basics of Copper Plumbing Soldering

Soldering copper plumbing is a crucial skill for both beginners and experienced plumbers. Whether you’re making repairs or installing new plumbing systems, soldering allows you to create strong and leak-free joints. In this article, we will explore the step-by-step process of how to solder copper plumbing successfully, ensuring your projects are completed efficiently and effectively.

Gathering the Necessary Tools and Materials

Before you begin soldering copper plumbing, it’s essential to gather all the necessary tools and materials. Here are the items you will need:

- Propane torch or soldering iron

- Lead-free solder

- Copper pipes and fittings

- Flux paste or liquid flux

- Cleaning materials (emery cloth, wire brush, or sandpaper)

- Pipe cutter or hacksaw

- Flame-resistant cloth or heat-resistant mat

- Pipe reamer or deburring tool

Once you have all the necessary tools and materials, you’re ready to begin the soldering process.

Preparing the Copper Pipes and Fittings

Before soldering, it’s crucial to clean and prepare the copper pipes and fittings. Follow these steps:

Step 1: Cutting the Pipes

Using a pipe cutter or hacksaw, carefully cut the copper pipes to the desired length. Ensure the ends are smooth and free from burrs.

Step 2: Removing Burrs

Use a pipe reamer or deburring tool to remove any burrs or rough edges from the inside and outside of the pipes. This step ensures proper fitment and helps prevent leaks.

Step 3: Cleaning the Pipes and Fittings

Next, clean the pipes and fittings using emery cloth, a wire brush, or sandpaper. This removes dirt, oxidation, and other debris that can interfere with the soldering process.

Step 4: Applying Flux

Apply flux paste or liquid flux to the cleaned surfaces of the pipes and fittings. Flux helps to remove oxidation and facilitates proper solder adhesion.

Soldering the Copper Plumbing Joints

Now that your copper pipes and fittings are prepared, it’s time to move on to the actual soldering process. Follow these steps:

Step 1: Assembling the Joints

Slide the pipes into the fittings and ensure they fit snugly. Make sure the alignment is correct and that there are no obstructions or misalignments along the joint.

Step 2: Heating the Joint

Using a propane torch or soldering iron, heat the joint evenly and slowly. Move the flame around the joint to distribute the heat uniformly. The joint should be heated until the flux bubbles and turns brown.

Step 3: Applying Solder

Once the joint is hot enough, touch the tip of the solder to the joint. If the joint is at the correct temperature, the solder will melt and flow smoothly into the joint. Continue applying the solder until it forms a complete and sealed joint.

Inspecting and Finishing the Soldered Joints

After soldering, it’s crucial to inspect your joints and ensure they are properly sealed. Follow these steps:

Step 1: Cooling the Joints

Allow the soldered joints to cool naturally. Trying to cool them by force or with water can cause damage to the joints.

Step 2: Inspecting for Leaks

Once the joints have cooled, visually inspect them for any signs of leaks. Additionally, you can perform a water pressure test to ensure the joints hold under pressure.

Step 3: Cleaning the Joints

Lastly, clean the soldered joints using a damp cloth to remove any excess flux or solder residue.

Ensuring the Success of Your Copper Plumbing Soldering Projects

Soldering copper plumbing requires precision, patience, and attention to detail. By following the proper techniques and steps, you can ensure successful soldered joints that are durable and leak-free. Remember to always prioritize safety, wear appropriate protective gear, and take necessary precautions when working with open flames and high temperatures.

Soldering Copper Plumbing: A Professional Guide

Soldering copper plumbing is an essential skill for any professional plumber. It allows for secure and leak-free connections in copper pipes and fittings. Here are the steps to solder copper plumbing:

- Prepare the surfaces: Clean and flux both the pipe and fitting to ensure proper adhesion.

- Heat the joint: Use a propane torch or soldering iron to heat the joint evenly.

- Apply solder: Once the joint is heated, touch the solder wire to the joint. The solder will melt and flow into the connection.

- Inspect the joint: After cooling, inspect the joint for any irregularities or leaks. Properly soldered joints should be smooth and shiny.

- Practice safety measures: Wear protective equipment, such as gloves and goggles, to prevent burns and eye injuries.

Remember, proper technique and adequate preparation are crucial for successful soldering. Practice on scrap copper and seek guidance from professionals if needed. With practice and experience, soldering copper plumbing will become a valuable skill in your professional repertoire.

Key Takeaways: How To Solder Copper Plumbing?

- Prepare your workspace by cleaning the copper pipes and removing any debris.

- Apply flux to the joint area to prevent oxidation and ensure a strong bond.

- Heat the joint evenly using a propane torch until the copper reaches the desired temperature.

- Apply solder to the joint, allowing it to flow and create a secure connection.

- After soldering, let the joint cool before testing for leaks. Always follow safety precautions while soldering.

Frequently Asked Questions

If you’re looking to tackle a plumbing project involving copper pipes, soldering is an essential skill to learn. Whether you’re repairing a leak or installing new plumbing, soldering copper pipes together is a reliable method for creating watertight connections. Here are some frequently asked questions about how to solder copper plumbing.

1. What type of solder should I use for copper plumbing?

When it comes to soldering copper plumbing, it’s important to use the right type of solder. The most commonly used solder for copper pipes is called lead-free solder. This type of solder is safe for potable water systems and does not contain harmful lead.

Lead-free solder typically consists of a mixture of tin and copper, sometimes with additional metals like silver for added strength. It has a lower melting point compared to other solders, making it easier to work with when soldering copper pipes.

2. How do I prepare the copper pipes for soldering?

Proper preparation of the copper pipes is crucial to achieve a strong and leak-free solder joint. Before soldering, make sure to clean the outside of the pipes and the inside of the fittings with a wire brush or sandpaper. This removes any dirt, oxidation, or grease that could prevent the solder from adhering properly.

After cleaning, apply flux to the areas that will be soldered. Flux is a chemical compound that helps remove oxidation and promotes the flow of solder. Coat the inside of the fittings and the outside of the pipes with a thin layer of flux. This will ensure a clean and reliable solder joint.

3. What equipment do I need for soldering copper plumbing?

To solder copper plumbing, you’ll need a few basic tools and equipment:

– A propane torch or a soldering iron with a flame attachment

– Lead-free solder

– Flux

– Wire brush or sandpaper for cleaning the pipes and fittings

– Pipe cutter or hacksaw to cut the copper pipes to the desired length

4. What are the steps to solder copper plumbing?

The steps to solder copper plumbing are as follows:

1. Cut the copper pipes to the desired lengths using a pipe cutter or hacksaw.

2. Clean the outside of the pipes and the inside of the fittings with a wire brush or sandpaper.

3. Apply flux to the areas that will be soldered, including the inside of the fittings and the outside of the pipes.

4. Assemble the pipes and fittings, ensuring a tight fit.

5. Heat the joint using a propane torch or soldering iron until the flux starts to bubble and the pipes are hot enough to melt solder.

6. Touch the end of the solder wire to the joint and allow it to melt and flow into the connection.

7. Remove the heat source and let the soldered joint cool and solidify.

5. How do I ensure a proper solder joint?

To ensure a proper solder joint when soldering copper plumbing, follow these tips:

– Ensure the pipes and fittings are clean and free from dirt, grease, and oxidation.

– Apply flux to the areas that will be soldered for better adhesion and flow of solder.

– Heat the joint evenly, moving the heat source around to prevent overheating one area.

– Use the correct amount of solder – enough to fill the joint completely without excessive drips.

– Inspect the soldered joint visually to ensure it is smooth and has filled the entire joint.

– Test the solder joint by pressurizing the system and checking

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

In conclusion, soldering copper plumbing is a simple process that can be done with a few basic tools and some practice. It involves cleaning the pipes, applying flux, heating the joint, and applying solder to create a strong and leak-proof connection.

Remember to always prioritize safety by wearing protective gear such as gloves and safety glasses. Take your time and ensure all surfaces are clean and dry before starting the soldering process. With the right techniques and a little patience, you can confidently tackle any copper plumbing soldering project.