Are you looking to learn how to connect plumbing pipes? Plumbing is an essential part of any building’s infrastructure, and understanding how to properly connect pipes is crucial for maintaining a functioning plumbing system. Whether you’re a homeowner tackling a DIY project or a professional plumber looking to refresh your knowledge, this guide will provide you with the necessary steps to ensure a secure and leak-free connection.

When it comes to connecting plumbing pipes, it’s important to have a basic understanding of the different types of pipes and fittings available. The most common types of pipes used in plumbing systems include copper, PVC, and PEX. Each material has its own advantages and considerations, so it’s essential to choose the appropriate pipe for your specific project. Additionally, selecting the right fittings is crucial for ensuring a tight and durable connection. Whether it’s soldering copper pipes, gluing PVC pipes, or using compression fittings for PEX, following the manufacturer’s instructions and understanding the proper techniques will help you achieve a successful connection every time.

To connect plumbing pipes, follow these professional steps:

- Measure and cut the pipes to the desired length.

- Debur the edges to remove any roughness.

- Clean the pipes and fittings with a solvent cleaner.

- Apply PVC primer to the outside of the pipes and the inside of the fittings.

- Apply PVC cement to the primed areas and quickly join the pipes and fittings together.

- Hold the joints in place for a few seconds to ensure a proper bond.

- Allow the cement to dry thoroughly before turning on the water.

By following these steps, you can successfully connect plumbing pipes in a professional manner.

Common Types of Plumbing Pipes

Before learning about how to connect plumbing pipes, it’s important to understand the different types of plumbing pipes commonly used in residential and commercial buildings. Each type of pipe has its own unique characteristics and requires specific techniques for connecting them.

1. Copper Pipes

Copper pipes are one of the most popular choices for plumbing installations due to their durability, resistance to corrosion, and ability to handle high-pressure systems. These pipes are available in rigid form (hard copper piping) and flexible form (soft copper piping). Hard copper piping is commonly used for water supply lines, while soft copper piping is often used for gas supply lines.

When connecting copper pipes, two popular methods are used, namely soldering and compression fittings. Soldering involves heating the copper pipes and applying solder to create a strong bond, while compression fittings use a compression nut and ring to secure the connection without the need for heat.

It’s crucial to clean the copper pipe thoroughly before making any connections and ensure a tight fit to prevent leaks. Additionally, using pipe deburring tools and flux can help achieve a proper connection.

2. PVC Pipes

PVC (Polyvinyl Chloride) pipes are commonly used for drainage systems, vent pipes, and cold water supply lines. They are lightweight, affordable, and resistant to chemicals, making them a popular choice for plumbing installations.

To connect PVC pipes, solvent welding is typically used. Solvent welding involves using a primer and PVC cement to join the pipes together. The primer cleans and softens the PVC surface, while the cement creates a chemical bond that fuses the pipes.

When connecting PVC pipes, it’s important to ensure the pipes are cut square and smooth to achieve a proper fit. Aligning the pipes correctly and allowing sufficient curing time for the solvent weld are also crucial steps for a successful connection.

3. PEX Pipes

PEX (Cross-linked Polyethylene) pipes are gaining popularity in plumbing systems due to their flexibility, resistance to freezing temperatures, and ease of installation. PEX pipes are often used for both hot and cold water supply lines.

Connecting PEX pipes typically involves the use of push-to-connect fittings or crimp fittings. Push-to-connect fittings feature a metal collar that securely holds the PEX pipe in place without the need for any tools. Crimp fittings, on the other hand, require a crimping tool to compress a metal ring around the connections for a tight seal.

It’s essential to cut the PEX pipe cleanly and ensure it is free of any debris or burrs before making any connections. The use of the appropriate fittings and tools recommended by the manufacturer is crucial to achieving a reliable connection.

4. Galvanized Steel Pipes

Galvanized steel pipes were commonly used in older plumbing systems but have become less popular in recent years. These pipes are coated with zinc to prevent rust and corrosion.

To connect galvanized steel pipes, threaded fittings are typically used. These fittings feature male and female ends that screw together to create a secure connection. Teflon tape or joint compound is applied to the threads to ensure a watertight seal.

When working with galvanized steel pipes, it’s important to inspect the condition of the pipes and fittings for any signs of corrosion or damage. Replacing worn-out pipes and fittings is crucial to prevent leaks and maintain the integrity of the plumbing system.

Connecting Plumbing Pipes: Best Practices

When connecting plumbing pipes, there are several best practices to follow to ensure a reliable connection and prevent leaks:

- Measure and cut the pipes accurately to achieve precise connections.

- Debur the edges of the pipes to remove any rough or sharp edges.

- Clean the pipes and fittings thoroughly to remove dirt, grease, and debris.

- Use the appropriate connectors or fittings recommended for the specific type of pipe being used.

- Apply the necessary sealing agents, such as solder, flux, primer, or cement, according to the pipe material and connection method.

- Follow the manufacturer’s instructions and guidelines for the specific pipe and fitting system being used.

- Inspect the connections for any signs of leaks or gaps and make any necessary adjustments or repairs.

- Ensure proper support and alignment of the pipes to prevent stress on the connections.

- Test the connections for leaks before covering or concealing them.

Safety Precautions

When working with plumbing pipes, it’s essential to prioritize safety. Here are some important safety precautions to follow:

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect against potential hazards.

- Use tools and equipment correctly and safely, following the manufacturer’s instructions.

- Shut off the water supply to the area where the work is being done to avoid accidental flooding.

- Be cautious when using open flames or heat sources for soldering or welding pipes.

- Ensure proper ventilation in enclosed spaces to prevent the buildup of hazardous fumes.

- Follow local building codes and regulations to ensure compliance and safety.

Importance of Professional Help

While basic plumbing connections can often be done by homeowners with the necessary skills and knowledge, more complex or extensive plumbing projects may require professional help. Hiring a licensed plumber ensures that the plumbing system is installed and connected correctly, minimizing the risk of future leaks and other issues.

Professional plumbers have the expertise, specialized tools, and experience to handle various types of plumbing pipes and connections. They can also provide valuable advice and recommendations for the most suitable materials and techniques to use in specific situations.

It’s important to keep in mind that plumbing connections can significantly impact the overall functionality and longevity of the plumbing system. Proper installation and connection methods are crucial for maintaining a reliable and leak-free plumbing system.

Connecting Plumbing Pipes: A Professional Guide

To successfully connect plumbing pipes, it is crucial to follow industry standards and best practices. Here are some essential steps to ensure a proper connection:

- Measure and Cut: Accurately measure the pipes and cut them to the desired length using a pipe cutter.

- Clean and Deburr: Use sandpaper or a deburring tool to remove rough edges and burrs from the cut ends of the pipes.

- Apply Primer: Apply a layer of primer on the outside of the pipe and the inside of the fitting to enhance adhesion.

- Apply Cement: Apply PVC cement evenly to both the pipe and fitting. Ensure complete coverage.

- Assemble: Quickly insert the pipe into the fitting, giving it a slight twist to ensure a secure connection. Hold in place for a few seconds.

- Test: Allow the cement to cure as recommended by the manufacturer, then perform a pressure test to check for any leaks.

Remember, it is crucial to select the appropriate type of pipes and fittings for your specific plumbing system. If you are unsure about any step or lack experience, it is advised to consult a professional plumber for assistance. Following these guidelines will help ensure a reliable and long-lasting plumbing connection.

Key Takeaways

- Measure and cut the pipe to the required length.

- Use a pipe cutter or hacksaw for a clean cut.

- Debur the cut end of the pipe to remove any sharp edges.

- Apply primer and then solvent cement to the pipe and fittings.

- Join the pipe and fittings together and twist them to ensure a secure connection.

Frequently Asked Questions

Connecting plumbing pipes is an essential part of any plumbing project. Whether you’re repairing a leak or installing new pipes, understanding how to connect them correctly is crucial. Below are some frequently asked questions about connecting plumbing pipes that can help guide you through the process.

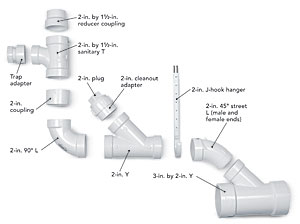

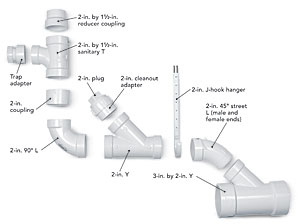

1. What are the different types of pipe connectors?

There are several types of pipe connectors commonly used in plumbing:

– Compression fittings: these fittings use a brass or plastic ring to compress the pipe, creating a watertight seal.

– Push-fit fittings: these fittings have a rubber O-ring that creates a secure connection when the pipe is pushed into the fitting.

– Soldered fittings: these fittings require soldering to create a bond between the pipes.

– Threaded fittings: these fittings have male and female threads that screw together to create a tight seal.

2. What is the process for connecting PVC pipes?

Connecting PVC pipes involves the following steps:

1. Measure and cut the PVC pipes to the desired length using a PVC cutter or saw.

2. Clean the ends of the pipes and fittings with PVC primer to remove any dirt and oils.

3. Apply PVC cement to the inside of the fitting and the outside of the pipe.

4. Quickly insert the pipe into the fitting, making sure it’s fully inserted and aligned.

5. Hold the joint together for a few seconds to allow the PVC cement to bond.

3. How do you connect copper pipes?

Connecting copper pipes can be done using soldered fittings. Here’s the process:

1. Clean the ends of the copper pipes and fittings using emery cloth or a wire brush.

2. Apply flux to the cleaned ends of the pipes and fittings.

3. Insert the pipes into the fittings, ensuring a snug fit.

4. Heat the joint using a propane torch until the flux begins to bubble.

5. Touch the solder to the joint, allowing it to flow into the connection.

4. Can you connect different types of pipes together?

Yes, it is possible to connect different types of pipes together using specific fittings. For example:

– PVC to copper: use a PVC to copper transition fitting.

– PVC to PEX: use a PVC to PEX transition fitting.

– Copper to galvanized steel: use a dielectric union to prevent corrosion.

Always consult a professional plumber or refer to the manufacturer’s guidelines for specific instructions when connecting different types of pipes.

5. How do you ensure a watertight connection when connecting pipes?

To ensure a watertight connection when connecting pipes, you can follow these steps:

1. Use the correct type of fitting for the pipes you are connecting.

2. Clean and prepare the pipes and fittings properly, removing any dirt, grease, or corrosion.

3. Apply the appropriate adhesive, cement, or soldering material according to the pipe material.

4. Ensure a tight and secure connection by fully inserting the pipe into the fitting or soldering joint.

5. Follow the manufacturer’s guidelines for curing or setting time to allow the adhesive or solder to properly bond.

How to connect plumbing PVC pipes together like a pro

In this article, we have discussed the basics of connecting plumbing pipes. We learned about different types of pipes, such as PVC, copper, and PEX, and how to choose the right fittings for each one. We also explored the steps involved in connecting pipes, including measuring and cutting the pipes, preparing the fittings, and using appropriate methods like soldering, gluing, or crimping.

Remember, safety is crucial when working with plumbing pipes, so always wear protective gear and follow local building codes. If you’re unsure about any step, it’s best to consult a professional plumber. By mastering the art of connecting plumbing pipes, you’ll be able to handle basic plumbing repairs and installations with confidence.