Valves in plumbing play a crucial role in regulating the flow of water and other fluids through pipes. Without valves, controlling the water supply and managing the various plumbing fixtures would be a daunting task. These small but mighty devices act as gatekeepers, allowing the user to start, stop, or adjust the flow as needed. From faucets to toilets to showers, valves ensure that water flows smoothly, efficiently, and at the desired pressure.

Valves have a rich history dating back thousands of years. In ancient civilizations, such as Egypt and Mesopotamia, rudimentary valve-like structures were used to control the flow of water for irrigation and other purposes. Over time, various types of valves were developed, including gate valves, globe valves, ball valves, and check valves, each with its unique design and function. Today, modern plumbing systems utilize these different types of valves to provide reliable water supply and prevent leaks and unnecessary wastage. In fact, according to a study by the Environmental Protection Agency, a leaking faucet that drips at a rate of one drip per second can waste over 3,000 gallons of water per year. Properly functioning valves can help address such issues and promote water conservation.

A valve in plumbing is a device that controls the flow of water or other fluids in a plumbing system. It can be used to start, stop, or regulate the flow of water, allowing for easy repairs or maintenance. There are different types of valves, including ball valves, gate valves, and check valves, each serving a specific purpose. Valves are an essential component in plumbing systems, ensuring proper water supply and preventing leaks or water damage.

Types of Valves Used in Plumbing

Valves play a crucial role in plumbing systems, controlling the flow of water, gas, or other fluids. There are various types of valves used in plumbing, each designed for specific functions and applications. Understanding the different types of valves can help homeowners and professionals make informed decisions when it comes to plumbing installations and repairs.

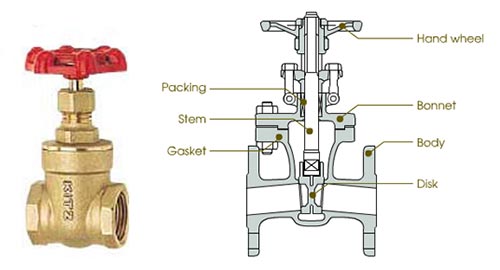

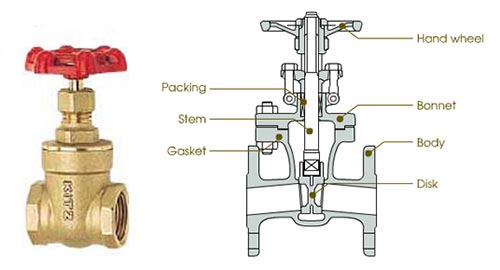

1. Gate Valve

Gate valves are one of the most commonly used valves in plumbing systems. These valves have a flat or wedge-shaped gate that is lowered or raised to control the flow of fluids. When the gate is fully raised, the valve is open, allowing the fluid to pass through. Conversely, when the gate is fully lowered, the valve is closed, preventing the fluid from flowing.

Gate valves are known for their excellent shut-off capability, making them ideal for situations where complete isolation of the fluid is desired. They are commonly used in water supply lines, irrigation systems, and other applications where on/off control is required. However, gate valves are not suitable for regulating fluid flow because they are designed to be fully open or fully closed.

It’s important to note that gate valves require more space for installation compared to other types of valves. They are also prone to corrosion and can become difficult to operate over time. Regular maintenance is essential to ensure their proper functioning.

Advantages of Gate Valves

- Excellent shut-off capability

- Simple design

- Cost-effective

Disadvantages of Gate Valves

- Not suitable for regulating flow

- Require more space for installation

- Prone to corrosion

2. Ball Valve

Ball valves are another common type of valve used in plumbing systems. They feature a spherical disc (the ball) with a hole in the middle that controls the flow of fluids. When the handle is turned parallel to the pipe, the ball is positioned to allow the fluid to flow. When the handle is perpendicular to the pipe, the ball is closed, preventing the flow.

Ball valves offer excellent shut-off capabilities and are widely used in applications where precise control over the flow of fluids is required. They are commonly seen in water supply lines, faucets, and appliances. Ball valves are also known for their durability and resistance to corrosion, making them a reliable choice for plumbing systems.

One advantage of ball valves is their versatility, as they can be used for both on/off control and regulating flow. However, it’s worth noting that ball valves can be more expensive than other types of valves, especially those with advanced features or made from high-quality materials.

Advantages of Ball Valves

- Excellent shut-off capability

- Versatility (can be used for on/off control and regulating flow)

- Durable and corrosion-resistant

Disadvantages of Ball Valves

- Can be more expensive than other types of valves

3. Globe Valve

Globe valves are widely used in plumbing systems due to their excellent flow control capabilities. These valves feature a movable disk (the plug) that regulates the flow of fluids by adjusting its position in relation to the stationary ring seat. When the plug is lifted, the valve is open, allowing fluid to flow. When the plug is lowered, the valve is closed, stopping the flow.

Globe valves are popular in applications where precise control over the flow rate is required, such as in water supply lines and industrial settings. They offer good shut-off capabilities and can withstand high pressures.

One drawback of globe valves is their complex design, which can make them more expensive than other types of valves. Additionally, their construction may facilitate the accumulation of debris, which can affect their performance over time. Regular maintenance and cleaning are necessary to ensure their optimal functioning.

Advantages of Globe Valves

- Excellent flow control

- Good shut-off capability

- Can handle high pressures

Disadvantages of Globe Valves

- Complex design

- Can be more expensive than other types of valves

- Potential accumulation of debris

4. Check Valve

A check valve, also known as a non-return valve, is designed to allow the flow of fluid in only one direction while preventing backflow. It consists of a movable disk or a ball that opens in the direction of the fluid flow and closes to prevent reverse flow. Check valves are commonly used in plumbing systems to prevent backflow of wastewater or gases.

Check valves can be found in various sizes and designs, including swing check valves, lift check valves, and ball check valves. They are essential for maintaining the integrity and safety of plumbing systems, ensuring that fluids flow in the intended direction.

One disadvantage of check valves is that they can sometimes experience wear and tear due to the constant movement of the movable disk or ball. Regular inspections and maintenance are necessary to ensure their proper functioning and prevent any potential issues.

Advantages of Check Valves

- Prevents backflow

- Ensures the integrity and safety of plumbing systems

Disadvantages of Check Valves

- May require regular inspections and maintenance

Valves play an essential role in plumbing systems, providing control over the flow of fluids. Understanding the different types of valves available can help homeowners and professionals select the most suitable options for their specific needs. Whether it’s a gate valve for on/off control, a ball valve for versatile applications, a globe valve for precise flow control, or a check valve for preventing backflow, each type serves a unique purpose in maintaining efficient and reliable plumbing systems.

Valve in Plumbing

In plumbing, a valve is a device used to control and regulate the flow of fluid in a pipe or system. It is an essential component that allows for the isolation and control of water, gas, or other liquids in residential, commercial, and industrial settings.

Valves can be found in various parts of a plumbing system, such as faucets, toilets, showers, and water heaters. They are designed to start and stop the flow of water, adjust the flow rate, and redirect the flow to different pipes or outlets.

There are different types of valves used in plumbing, including ball valves, gate valves, globe valves, and check valves. Each type has its own function and purpose, such as preventing backflow, regulating pressure, or shutting off water supply.

Valves are typically made of materials such as brass, stainless steel, or PVC, depending on their application and the type of fluid being controlled. They can be operated manually, automatically, or through remote control systems.

Overall, valves play a crucial role in plumbing systems by providing control, efficiency, and safety in the distribution and use of fluids.

Key Takeaways for “What Is Valve In Plumbing?”

- Valves are devices used to control the flow of water or other fluids in plumbing systems.

- They play a crucial role in regulating water supply and shutting off the flow when needed.

- There are various types of valves used in plumbing, including gate valves, ball valves, and globe valves.

- Gate valves are commonly used to fully open or fully close the flow of water.

- Ball valves are versatile and can control the flow at different levels.

Frequently Asked Questions

In this section, we will answer some commonly asked questions about valves in plumbing.

1. How does a valve work in plumbing?

A valve in plumbing is a device used to control the flow of liquid or gas through a pipe. It works by opening or closing to allow or restrict the flow. When the valve is closed, it blocks the passage of the fluid, and when it is open, it allows the fluid to pass through. Valves typically have a handle or lever that is manually operated to control the opening and closing.

There are different types of valves used in plumbing, such as gate valves, ball valves, and globe valves. Each type has its own mechanism for controlling the flow, but the basic principle is the same – to regulate the flow of fluid in a pipe.

2. Why are valves important in plumbing systems?

Valves are essential components in plumbing systems for several reasons:

1. Regulation of Flow: Valves allow for the control and regulation of the flow of water or gas in the plumbing system. This is important for different applications, such as adjusting water pressure or shutting off the water supply in case of emergencies.

2. Maintenance and Repairs: Valves allow for the isolation of specific sections of the plumbing system, making it easier to perform maintenance or repairs without shutting off the entire system. This reduces downtime and inconvenience.

3. What are the different types of valves used in plumbing?

There are several types of valves commonly used in plumbing:

1. Gate Valves: These valves have a sliding gate that controls the flow of fluid. They are typically used to shut off or allow full flow, rather than regulating the flow.

2. Ball Valves: These valves have a ball with a hole in the middle. When the ball is rotated, the hole aligns with the pipe, allowing flow, or blocks the pipe, stopping the flow. They are commonly used for on/off applications.

3. Globe Valves: These valves have a disk or plug that controls the flow by moving up and down or rotating. They are commonly used for regulating the flow of fluid.

4. How do you maintain valves in plumbing systems?

Maintaining valves in plumbing systems is essential to ensure their proper functioning. Here are some maintenance tips:

1. Regular Inspection: Check valves periodically for any signs of leaks, corrosion, or damage. Replace any faulty valves immediately.

2. Lubrication: Apply a lubricant to moving parts of the valve to prevent stiffness or sticking.

3. Exercise Valves: Operate valves periodically to keep them from getting stuck due to lack of use.

5. Can valves be repaired or do they need to be replaced?

Whether a valve needs to be repaired or replaced depends on the extent of the damage and the type of valve. In some cases, a simple repair, such as replacing a worn-out seal or gasket, might be sufficient. However, if the valve is severely damaged or corroded, it is often more cost-effective and reliable to replace it entirely.

It is recommended to consult a professional plumber to assess the condition of the valve and determine the best course of action.

Types of Water Valves – Plumbing Valve Types

In conclusion, a valve in plumbing is a device used to control the flow of water or other fluids through pipes. It plays a crucial role in regulating the water supply and preventing leaks or water damage in a plumbing system.

There are different types of valves used in plumbing, including ball valves, gate valves, and check valves. Each type has its own specific functions and features. Understanding the purpose and operation of valves is essential for any homeowner or plumber to ensure proper maintenance and troubleshooting of a plumbing system.