When it comes to plumbing a well pump, there are key considerations that can make the process smoother and more efficient. Did you know that proper installation and maintenance of a well pump can significantly impact the functionality and lifespan of your water system? Ensuring that the pump is plumbed correctly not only maximizes its performance but also helps prevent potential issues down the line.

Understanding the essentials of how to plumb a well pump is essential for any professional plumber. It involves a combination of technical knowledge, practical skills, and attention to detail. One crucial aspect is understanding the history and background of well pumps, as well as the role they play in providing reliable water supply. Additionally, incorporating relevant statistics and highlighting practical solutions can help professionals approach well pump plumbing with confidence and expertise.

To plumb a well pump in a professional manner, follow these steps:<\p>

- Start by shutting off the power to the pump and pressure tank.

- Disconnect the existing piping from the pump.

- Attach the new piping to the pump, ensuring a secure connection.

- Install a check valve to prevent backflow.

- Connect the piping to the pressure tank using a T-connector.

- Turn the power back on and test the pump for proper functioning.

Understanding the Basics of Well Pump Plumbin

Plumbing a well pump is a crucial step in ensuring a reliable water supply for your household. Whether you’re installing a new well pump or replacing an old one, understanding the basics of well pump plumbing is essential. This comprehensive guide will walk you through the process, covering everything from selecting the right pump to the actual installation and troubleshooting common issues. So, let’s dive in and learn how to plumb a well pump effectively.

Selecting the Right Well Pump

The first step in plumbing a well pump is selecting the right pump for your well. Well pumps come in various types and sizes, so it’s crucial to choose one that suits your specific needs. The two most common types of well pumps are submersible and jet pumps.

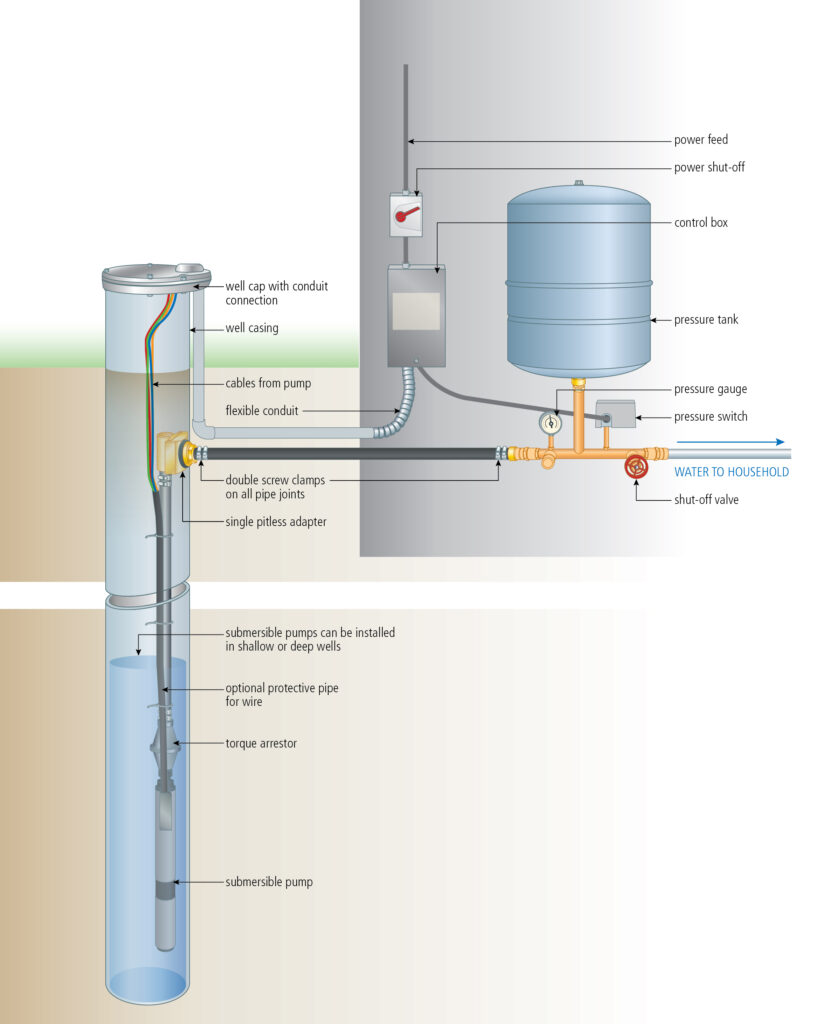

Submersible pumps are installed deep inside the well and push water up to the surface. They are typically used for deeper wells and provide higher water pressure. Jet pumps, on the other hand, are installed above ground and use suction to pull water from the well. They are more suitable for shallower wells and have lower water pressure compared to submersible pumps.

When selecting a well pump, consider factors such as well depth, water demand, and power supply. Consult with a professional or refer to the manufacturer’s guidelines to ensure you choose the right pump for your specific well.

Gathering the Required Tools and Materials

Before you begin the installation process, gather all the necessary tools and materials. This will ensure a smooth and efficient plumbing process. Here are some of the essential tools and materials you’ll need:

- Pipe wrench

- Teflon tape

- Well tank

- Pressure switch

- Pressure gauge

- Check valve

- PVC pipes and fittings

Installing the Well Pump

Now that you have the right pump and all the necessary tools and materials, it’s time to install the well pump. Follow these steps:

1. Turn off the power to the well pump at the circuit breaker.

2. Disconnect the existing plumbing from the old pump, including the electrical connections, pipes, and fittings.

3. Lower the new pump into the well, ensuring that it is suspended at an appropriate depth. Refer to the manufacturer’s guidelines for the correct placement.

4. Connect the pump to the well’s water supply line, making sure to use Teflon tape or pipe dope on all threaded connections to prevent leaks.

5. Install the pressure switch, pressure gauge, check valve, and well tank according to the manufacturer’s instructions. These components will help regulate water pressure and ensure smooth operation of the well pump.

Testing and Troubleshooting

Once the well pump is installed, it’s essential to test it and troubleshoot any issues that may arise. Follow these steps to ensure the well pump is functioning correctly:

1. Turn on the power to the well pump at the circuit breaker.

2. Run water from multiple faucets in your home to check for consistent water flow and pressure. If there are any issues, such as low pressure or intermittent flow, consider checking the pressure switch settings or consulting with a professional.

3. Monitor the well pump’s operation for any unusual noises or vibrations. These can indicate a problem with the pump or the installation and may require further investigation.

If you encounter any issues during the testing process, it’s advisable to seek assistance from a professional well pump technician. They can diagnose and resolve any problems more effectively.

Regular Maintenance and Upkeep

To ensure the longevity and efficiency of your well pump, regular maintenance and upkeep are necessary. Here are some tips to keep your well pump in optimal condition:

1. Regularly inspect the well pump and all its components for signs of damage or wear. Replace any faulty parts promptly.

2. Test the pressure switch and adjust as needed to maintain the desired water pressure.

3. Have the well water tested periodically to ensure it is free from contaminants and safe for use.

Deep Submersible Well Pump Installation. Educational Guide

3. Have the well water tested periodically to ensure it is free from contaminants and safe for use.

4. Schedule professional maintenance and servicing at least once a year. This will involve a thorough inspection, cleaning, and potential repairs or replacements.

Understanding the Electrical Aspects of Well Pump Plumbing

In addition to the plumbing aspect, understanding the electrical aspects of well pump plumbing is crucial for a successful installation and operation. Here are some key points to consider:

Safety Measures

Working with electricity can be dangerous, so it’s essential to take proper safety precautions when plumbing a well pump:

- Always turn off power to the well pump at the circuit breaker before starting any work.

- Use insulated tools to prevent electrical shocks.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Consult with a professional electrician if you’re unsure about any electrical aspects of the installation.

Understanding Electrical Connections

Proper electrical connections are vital for the well pump to function correctly. Here’s an overview of the key electrical components and connections:

1. Power Supply: The well pump is typically connected to a 240V power supply. Ensure that the voltage matches the pump’s requirements and that the wiring is adequate for the load.

2. Pressure Switch: The pressure switch is responsible for turning the pump on and off based on the water pressure in the system. It is typically connected to the power supply and the well pump.

3. Control Box: Some well pumps, particularly submersible ones, require a control box for proper operation. The control box houses components such as capacitors and relays, which regulate the pump’s starting and running cycles.

Maintaining Electrical Components

To ensure the safety and optimal performance of the electrical components, regular maintenance is essential:

1. Inspect all wiring connections and terminals for signs of damage or corrosion. Replace any faulty wiring or connectors.

2. Test the pressure switch regularly to ensure it is functioning correctly. Adjust as needed to maintain the desired water pressure.

3. Check the control box and its components for any signs of wear or malfunctioning. Consult with a professional if you suspect any issues.

4. If you’re uncertain about any electrical maintenance tasks, it’s best to consult with a qualified electrician to ensure the job is done safely and correctly.

Importance of Grounding

Proper grounding is critical to protect against electrical faults and ensure the safety of the well pump system. Here are some key points to consider:

1. Well pumps should be connected to an adequate grounding system, typically consisting of grounding rods or plates installed near the well.

2. The grounding conductor should be properly sized and securely connected to both the well pump and the grounding system.

3. Regularly inspect the grounding system for any signs of damage or deterioration, and make any necessary repairs or replacements promptly.

Following proper grounding practices will minimize the risk of electrical shocks and ensure the well pump operates safely and effectively.

In conclusion, plumbing a well pump involves both the plumbing and electrical aspects of the installation. Selecting the right pump, gathering the necessary tools and materials, and following proper installation procedures are crucial for a successful plumbing project. Regular maintenance and troubleshooting can help identify and resolve any issues that may arise, ensuring a reliable water supply for your household. By understanding the basics of well pump plumbing and adhering to safety guidelines, you can confidently tackle this project or seek professional assistance if needed.

Plumbing a Well Pump: Professional Guidelines

Plumbing a well pump requires careful attention to ensure proper installation and functionality. Here are some professional guidelines to follow:

- Start by determining the location for the well pump, preferably in a dry, well-ventilated area.

- Choose the appropriate pipe material, usually PVC or polyethylene, for durability and resistance to corrosion.

- If using PVC pipes, use solvent cement for secure joints, ensuring a leak-free connection.

- Install a pressure tank to regulate water flow and maintain consistent pressure levels.

- Connect the well pump to the pressure tank using a pipe or hose, ensuring a tight seal.

- Ensure proper electrical wiring and connections, following local electrical codes.

- Prime the well pump by adding water to the system before starting it up.

- Test the well pump for proper functioning and water flow, adjusting settings if necessary.

- Regularly maintain and inspect the well pump to prevent issues and ensure longevity.

Following these professional guidelines will help you successfully plumb a well pump and ensure a reliable water supply. Remember to consult a professional or local regulations for specific requirements and safety measures.

Key Takeaways: How To Plumb A Well Pump?

- Choose the right well pump that fits your water needs.

- Install a well pressure tank to maintain consistent water pressure.

- Ensure proper piping connections for a secure and efficient plumbing system.

- Consider using a check valve to prevent backflow and protect the pump.

Frequently Asked Questions

Plumbing a well pump can be a complex task, but with the right knowledge and guidance, it can be done effectively. Here are some common questions related to plumbing a well pump and their answers.

1. What are the necessary steps to plumb a well pump?

In order to plumb a well pump, you need to follow these steps:

- Start by shutting off the power to the pump and draining the pressure tank.

- Remove the old pump and install a new one if necessary.

- Connect the pump to the discharge pipe using threaded connections or a flexible connector.

- Install a check valve on the discharge pipe to prevent backflow.

- Connect the pressure switch to the pump and wire it to the power supply.

- Prime the pump by pouring water into the suction pipe and filling the pump housing.

- Turn on the power to the pump and check for any leaks.

- Finally, open the valves in your plumbing system to allow the water to flow.

By following these steps, you can successfully plumb a well pump.

2. How do I determine the right size of pipes for my well pump?

The size of pipes for your well pump is determined by the flow rate and the distance the water needs to travel. Here’s a general guideline:

- For flow rates of 10 GPM (gallons per minute) or less, use 1-inch pipes.

- For flow rates between 10-20 GPM, use 1.25-inch pipes.

- For flow rates between 20-40 GPM, use 1.5-inch pipes.

- For flow rates above 40 GPM, consult a professional plumber.

Using the right size of pipes ensures efficient water flow and minimizes pressure loss in your plumbing system.

3. How often should I replace my well pump?

The lifespan of a well pump depends on various factors such as usage, water quality, and maintenance. In general, well pumps can last anywhere from 10 to 20 years. However, if you notice signs of reduced water pressure, frequent cycling, or abnormal noise, it may be time to replace your well pump.

Regular maintenance and periodic inspection by a professional can help prolong the life of your well pump.

4. Can I install a well pump myself, or should I hire a professional?

While it is possible to install a well pump yourself, it is recommended to hire a professional plumber for this task. Plumbing a well pump involves electrical connections, proper pipe sizing, and potential hazards. A professional plumber will have the expertise and knowledge to ensure the installation is done correctly and safely.

Additionally, hiring a professional plumber may be required to comply with local building codes and regulations.

5. How can I maintain my well pump?

To keep your well pump in good working condition, follow these maintenance tips:

- Regularly check and clean the pump intake screen to prevent clogging.

- Test the pump pressure and adjust the pressure switch if necessary.

- Inspect the electrical connections for any signs of wear or damage.

- Ensure the well cap is securely sealed to prevent contamination.

- Schedule regular professional inspections to detect and address any issues promptly.

By following these maintenance practices, you can extend the lifespan of your well pump and avoid costly repairs.

Deep Submersible Well Pump Installation. Educational Guide

In conclusion, plumbing a well pump is a straightforward process that requires careful planning and attention to detail. It is essential to ensure that all necessary materials are gathered before starting the installation. Additionally, understanding the layout of the well system and following all safety guidelines is crucial for a successful plumbing job.

Remember to shut off the electricity and water supply before beginning any work. Start by connecting the water pipes to the well pump using appropriate fittings and secure them tightly. Then, connect the discharge pipe to direct water flow out of the pump and into the system. Finally, test the pump to ensure it is functioning correctly and make any necessary adjustments.