When it comes to plumbing connections, ensuring a secure seal is vital for preventing leaks and maintaining the integrity of the system. A minor issue like a leaking pipe joint can quickly escalate into a major headache, resulting in water damage and costly repairs. That’s why understanding how to properly seal plumbing connections is crucial for any professional plumber or DIY enthusiast.

One key aspect of sealing plumbing connections is using the right materials. In the past, plumbers primarily relied on traditional methods like pipe dope and thread tape. However, advancements in plumbing technology have introduced new options such as sealants and compression fittings, which offer improved durability and efficiency. According to a survey conducted by the Plumbing Manufacturers International, 85% of professional plumbers now prefer using sealants for sealing plumbing connections, due to their ease of use and long-term effectiveness.

Sealing plumbing connections is crucial to prevent leaks and maintain the integrity of your plumbing system. Follow these steps to ensure a proper seal:

- Start by cleaning the connection surfaces with a brush and mild detergent.

- Apply thread seal tape clockwise on pipe threads to create a tight seal.

- For compression fittings, insert the pipe into the fitting and tighten the nut with a wrench.

- Use pipe dope or plumber’s putty on threaded connections, applying it evenly.

- Check for any leaks by running water through the pipes.

Routine inspection and re-sealing is necessary to prevent future leaks. Hiring a professional plumber is recommended for complex installations.

The Importance of Properly Sealing Plumbing Connections

When it comes to plumbing, ensuring that connections are properly sealed is essential for preventing leaks and maintaining the integrity of your plumbing system. Whether you are installing new plumbing fixtures or repairing existing ones, using the right sealing techniques can help you avoid costly water damage and potential health hazards caused by mold and mildew growth.

Sealing plumbing connections involves creating a watertight barrier between different pipe sections, fittings, and fixtures. This helps to prevent any water or sewage from leaking out and causing damage to your property. Additionally, it ensures that contaminants, such as bacteria or insects, cannot enter your plumbing system and compromise water quality.

In this article, we will explore various methods and materials used for sealing plumbing connections. Whether you are a professional plumber or a DIY enthusiast, understanding these techniques will enable you to execute plumbing projects with confidence and ensure long-lasting results.

1. Threaded Connections

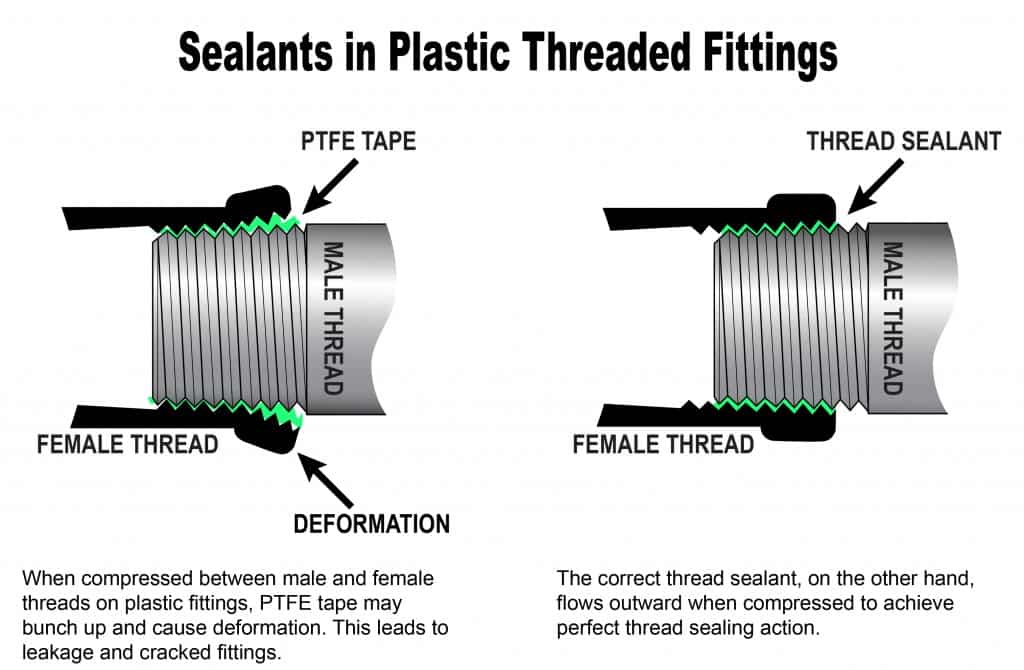

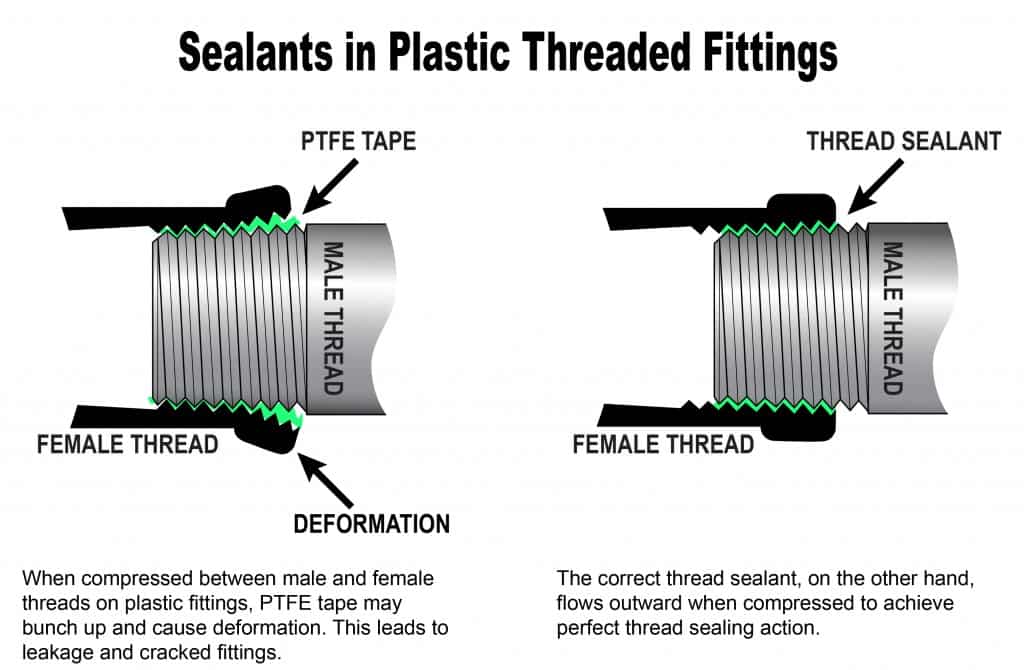

Threaded connections are commonly used in plumbing systems, especially for joining metal pipes and fittings together. To create a leak-free seal, it is crucial to apply the right type of sealant on the threads before tightening the connection. There are two primary types of sealants used for threaded connections:

- Teflon tape: This thin, white tape is wrapped around the male threads of a pipe or fitting. It acts as a lubricant, allowing the threads to be tightened more easily while providing a watertight seal.

- Pipe joint compound: Also known as pipe dope, this material is applied to the threads and provides a more robust seal. It typically comes in a paste-like form and is suitable for both metal and plastic threaded connections.

Before applying the sealant, ensure that the threads are clean and free from any debris or old sealant remnants. Begin by wrapping the Teflon tape tightly around the male threads in a clockwise direction. As for pipe joint compound, use a brush or your finger to evenly spread a thin layer over the threads.

Once the sealant is applied, carefully thread the connection together by hand. Use a wrench to tighten the connection slightly, ensuring that it is secure but not over-tightened. This will help prevent damage to the threads.

1.1 Common Mistakes to Avoid

While sealing threaded connections, there are a few common mistakes you should be aware of and avoid to maintain a proper seal. These include:

- Using excessive Teflon tape: Applying too much Teflon tape can cause the connection to become too tight and may result in cracked fittings or stripped threads.

- Applying pipe joint compound to the wrong side: To ensure an effective seal, pipe joint compound should only be applied to the male threads of the connection.

- Over-tightening the connection: Over-tightening can damage the threads or lead to leaks due to stress on the connection.

By avoiding these mistakes, you can achieve a proper seal and prevent potential issues in your plumbing system.

1.2 When to Use Thread Sealant

Thread sealant should be used in various plumbing applications to ensure leak-free connections. Some common instances where thread sealant is required include:

- Connecting water supply lines for faucets, toilets, and showers

- Joining pipes for water distribution systems

- Installing gas lines

- Connecting threaded valves and fittings

Always refer to the manufacturer’s instructions and plumbing codes for specific guidelines on when to use thread sealant.

2. Compression Connections

Compression fittings are commonly used to connect pipes and fixtures that require disassembly for maintenance or repair. These connections rely on a compression nut and ring to create a tight seal. To achieve a proper seal with compression fittings, follow these steps:

- Ensure the pipe end is cut cleanly and squarely.

- Slide the compression nut and ring onto the pipe.

- Insert the pipe into the fitting or valve body.

- Tighten the compression nut clockwise by hand until it is snug.

- Use a wrench to tighten the compression nut an additional 1/4 to 1/2 turn.

It’s crucial not to overtighten the compression nut, as this could lead to leaks or even damage the fitting. If necessary, follow the manufacturer’s instructions for specific tightening guidelines.

Compression fittings are commonly used in faucets, toilets, angle stops, and other plumbing fixtures that require easy disconnection for maintenance or replacement.

2.1 Common Mistakes to Avoid

When working with compression fittings, be cautious of these common mistakes:

- Failing to use a compression ring: The compression ring is essential for creating a watertight seal. Make sure to include it in the assembly.

- Overtightening the compression nut: Over-tightening can cause damage to the fitting or lead to leaks. Follow the manufacturer’s instructions for proper tightening.

- Not ensuring a clean cut on the pipe end: A clean and square cut ensures a proper fit and maximizes the sealing surface area.

Avoiding these common mistakes will help you achieve effective compression connections and prevent issues down the line.

3. Welding Connections

Welding is commonly used for joining metal pipes and fittings in plumbing systems. It provides a strong and permanent connection that is resistant to leaks when done correctly. Two popular welding methods in plumbing are soldering and brazing:

Soldering: Soldering involves melting a filler metal into the gap between two metal pieces to create a bond. It is typically used for copper pipes and fittings. To solder a connection:

- Clean the pipe and fitting using emery cloth or a wire brush to remove any oxidation or dirt.

- Apply flux to the cleaned surfaces to promote solder adhesion and prevent oxidation during the heating process.

- Heat the joint using a propane torch until the pipe and fitting reach the appropriate temperature.

- Apply solder to the joint; it should melt and flow into the gap through capillary action.

- Allow the joint to cool and solidify.

- Wipe away any excess flux or solder residue.

Brazing: Brazing is similar to soldering but involves using a filler metal with a higher melting point, usually brass or silver. It is suitable for higher-pressure plumbing applications. The process is similar to soldering, but higher temperatures are required.

Welding connections should be done with caution and proper safety measures, as it involves working with high temperatures and potentially hazardous materials.

3.1 Common Mistakes to Avoid

When welding connections, it is important to avoid these common mistakes:

- Insufficient cleaning: Failing to properly clean the surfaces before welding can result in weak or unreliable joints.

- Overheating: Excessive heat can damage pipes or fittings, impairing their functionality and leading to leaks.

- Failure to use flux: Flux is crucial for solder adhesion and preventing oxidation during the heating process.

- Using the wrong filler metal: Different metals require specific filler metals for proper bonding. Using the wrong one can result in weak connections.

By avoiding these mistakes, you can create strong and durable welded connections in your plumbing system that will last for years to come.

4. Adhesive Connections

Adhesive connections are commonly used in plastic plumbing systems and require the use of solvent cement to join pipes and fittings. The solvent cement chemically fuses the plastic components together, creating a strong and leak-free connection. Here are the steps for making adhesive connections:

- Clean the pipe end and fitting using a PVC cleaner or primer to remove any dirt or residue.

- Apply a layer of solvent cement to the pipe end and fitting socket.

- Quickly insert the pipe into the fitting socket, giving it a slight twist to spread the cement evenly.

- Hold the connection in place for a few seconds to allow the cement to set.

- Wipe away any excess cement.

It is crucial to use the appropriate solvent cement recommended by the manufacturer for the specific type of plastic piping being used. Different plastics require different types of cement for proper bonding.

4.1 Common Mistakes to Avoid

When working with adhesive connections, be aware of these common mistakes:

- Not using the correct solvent cement: Different types of plastic pipes require different types of solvent cement for proper bonding.

- Failing to clean the surfaces adequately: Proper cleaning ensures the best possible bond, so it is crucial not to skip this step.

- Using too much or too little cement: Applying an excessive amount of solvent cement can lead to messy joints, while using too little may result in weak connections.

- Not allowing sufficient curing time: It is important to follow the manufacturer’s instructions and allow the recommended cure time before pressurizing the system.

By avoiding these mistakes, you can achieve reliable and durable adhesive connections in your plastic plumbing system.

Conclusion

Properly sealing plumbing connections is crucial for preventing leaks, water damage, and maintaining the integrity of your plumbing system. Whether you are dealing with threaded connections, compression fittings, welding, or adhesive connections, following the correct techniques will ensure a long-lasting and leak-free plumbing system. By avoiding common mistakes and using the appropriate sealants and techniques, you can execute plumbing projects with confidence, whether you are a professional plumber or a DIY enthusiast.

How to Properly Seal Plumbing Connections

When it comes to plumbing connections, it is crucial to ensure they are properly sealed to prevent leaks and potential damage. Follow these steps to seal your plumbing connections effectively:

- Start by cleaning the surfaces that need to be sealed using a degreaser or solvent. This will remove any dirt, grease, or debris that could interfere with the seal.

- Apply plumber’s tape or Teflon tape to the threads of the pipe fitting. This helps create a tight seal and prevents leaks.

- Use a quality pipe joint compound, also known as pipe dope, on the threads before connecting the pipes. Apply a thin, even layer to ensure a proper seal.

- Tightly connect the pipes or fittings together, ensuring they are aligned correctly. Use a wrench or pliers to securely tighten them.

- Check for any visible gaps or leaks once the connection is tightened. If necessary, reapply the joint compound or tighten the connection further.

By following these steps and using the right materials, you can ensure that your plumbing connections are tightly sealed and leak-free. Proper sealing will help prevent water damage, improve the longevity of your plumbing system, and save you from costly repairs in the future.

Key Takeaways for “How To Seal Plumbing Connections?”

- Use plumber’s tape to ensure a tight seal on threaded connections.

- Apply pipe joint compound on threaded fittings for a secure connection.

- Use silicone caulk to seal non-threaded connections or gaps in pipes.

- Consider using plumber’s putty for certain sink and fixture connections.

- Regularly inspect and replace worn-out seals or gaskets to prevent leaks.

Frequently Asked Questions

Sealing plumbing connections is essential to avoid leaks and ensure the smooth functioning of your plumbing system. Here are some commonly asked questions regarding how to seal plumbing connections:

1. Can I use Teflon tape to seal plumbing connections?

Yes, Teflon tape is a commonly used method for sealing plumbing connections. It is a thin, white tape that is wrapped around the threads of plumbing pipes before connecting them. The tape provides a tight seal and helps prevent leaks. To use Teflon tape, simply wrap it in a clockwise direction around the male threads of the pipe, stretching it slightly as you go. Make sure to wrap it at least three times for a secure seal. Then, connect the pipes as usual.

It’s important to note that Teflon tape is not suitable for all types of plumbing connections. For example, it should not be used on PVC pipes or compression fittings, as they require different sealing methods. Always check the manufacturer’s instructions and consider using alternative methods if necessary.

2. What is pipe dope, and can I use it to seal plumbing connections?

Pipe dope, also known as thread sealant, is a paste-like substance used to seal the threads of plumbing connections. It is commonly used in combination with Teflon tape for a secure and leak-proof seal. Pipe dope can be applied directly to the male threads of the pipe before connecting them. It fills in any gaps or imperfections in the threads, providing an additional layer of sealing.

When using pipe dope, it’s important to choose the right type for the specific plumbing material you are working with. Some pipe dopes are designed for specific materials, such as copper or plastic, and using the wrong type can lead to compatibility issues. Always read the manufacturer’s instructions and follow the recommended application method for the best results.

3. Are rubber gaskets effective for sealing plumbing connections?

Yes, rubber gaskets are commonly used to seal plumbing connections, especially in applications where a watertight seal is required. Rubber gaskets are usually used with flanged pipe fittings, such as toilet flanges, and they provide a tight seal between the connecting surfaces. These gaskets are typically made of durable rubber and are resistant to water, chemicals, and pressure.

To use a rubber gasket for sealing a plumbing connection, place it between the two connecting surfaces and ensure that it is properly aligned. Then, tighten the bolts or screws to compress the gasket and create a watertight seal. It’s important to regularly inspect rubber gaskets for wear and tear and replace them if necessary to maintain the effectiveness of the seal.

4. Can I use pipe thread sealant tape instead of Teflon tape?

Yes, pipe thread sealant tape is an alternative to Teflon tape for sealing plumbing connections. This type of tape is specifically designed for pipe threads and offers similar benefits in terms of sealing and leak prevention. Pipe thread sealant tape is usually denser and thicker than Teflon tape, providing a more secure seal.

To use pipe thread sealant tape, apply it in a clockwise direction over the threads of the male pipe. Make sure to wrap it tightly and cover all the threads. After applying the tape, connect the pipes as usual. It’s important to note that pipe thread sealant tape should not be used on plastic or PVC pipes, as it can cause damage. Always follow the manufacturer’s instructions and consider the specific requirements of your plumbing system.

5. Are there any alternative methods for sealing plumbing connections?

Yes, there are several alternative methods for sealing plumbing connections, depending on the specific type of connection and the materials involved. Some other commonly used methods include:

– Pipe joint compound: This is a paste-like substance that is applied to the threads of plumbing connections. It provides a secure seal and is typically used in combination with Teflon tape or pipe thread sealant tape.

– Compression fittings: These fittings use a compression ring and nut to create a watertight seal. They are commonly used for connecting pipes with different materials, such as copper and plastic.

– Welding or soldering: These methods are used for sealing metal pipes together. They involve heating the pipes and applying solder or welding material to create a strong and durable seal.

When to Use Sealants on Threaded Plumbing Connections | This Old House

In conclusion, it is crucial to properly seal plumbing connections to prevent leaks and maintain the integrity of your plumbing system. To seal connections effectively, you can use various methods such as pipe dope, tape, or sealants.

Before sealing, make sure to clean the surfaces thoroughly and remove any dirt or debris that may hinder the sealing process. Apply the chosen sealing material evenly and firmly to ensure a tight seal. Additionally, always check for any leaks after making the connections and sealing them to address any issues promptly.