When it comes to plumbing, proper testing is essential for ensuring the integrity of the system. One useful tool in this process is the plumbing test ball, often used to block off pipes and conduct pressure tests. But how exactly does one use a plumbing test ball? Let’s dive in and find out!

A plumbing test ball is a flexible device that can be inserted into a pipe and then inflated to create a seal. This seal prevents water or air from passing through, allowing for accurate pressure testing. With its versatile design, a plumbing test ball can be used in various applications, from residential plumbing to industrial pipelines. By using a test ball, plumbers can quickly and efficiently identify leaks, blockages, or other issues in the system, saving time and resources. It’s a powerful tool in the hands of a skilled professional.

A plumbing test ball is a useful tool for testing and sealing pipes during plumbing repairs and installations. Here’s how to use it like a professional:

- First, identify the appropriate size of test ball for your pipe.

- Deflate the test ball and lubricate it with a water-based lubricant.

- Insert the deflated test ball into the pipe and use an air pump to inflate it.

- Check for any leaks by observing the pressure gauge on the pump.

- If there are no leaks, deflate the test ball and remove it from the pipe.

By following these steps, you can effectively use a plumbing test ball to ensure the integrity of your plumbing system.

Understanding the Importance of a Plumbing Test Ball

A plumbing test ball is an essential tool used in plumbing systems to create a temporary seal or blockage. Whether you’re a professional plumber or a homeowner tackling a plumbing project, understanding how to use a plumbing test ball can be beneficial. This article will guide you through the process of using a plumbing test ball effectively, ensuring a successful plumbing job and preventing leaks or other issues.

1. Choosing the Right Size and Type of Plumbing Test Ball

The first step in using a plumbing test ball is selecting the right size and type for your specific plumbing project. Plumbing test balls come in various sizes, from small diameters designed for residential pipelines to larger ones used in commercial or industrial applications. It’s crucial to choose a test ball that matches the pipe diameter you are working with. Consulting with a professional or referring to plumbing charts can help you determine the appropriate size.

In addition to size, you also need to consider the type of plumbing test ball you require. There are inflatable test balls that can be easily inserted and inflated within the pipe, providing an airtight seal. These are commonly used in drain, vent, and waste applications. Alternatively, mechanical test balls are non-inflatable and rely on a mechanical seal or plug to block the pipe. These types of test balls are typically used for temporary pipe repairs or for in-line testing.

Once you have determined the appropriate size and type of plumbing test ball, you can move on to the next step of using it effectively.

1.1 Preparing the Plumbing Test Ball

Before inserting the plumbing test ball into the pipe, you need to make sure it is properly prepared. Inflate the inflatable test balls according to the manufacturer’s instructions, ensuring that it reaches a suitable size to create an effective seal. If you are using a mechanical test ball, ensure that all components are securely attached, such as the plug or seals.

It’s also essential to inspect the plumbing test ball for any defects or damages before use. Check for any tears, holes, or signs of wear that could compromise its effectiveness. If you notice any issues, it is best to replace the test ball before proceeding.

Additionally, lubricating the plumbing test ball with a suitable lubricant can facilitate easier insertion and removal from the pipe. This step is particularly crucial when using inflatable test balls. Be sure to use a lubricant recommended by the manufacturer to avoid any damage to the test ball or the plumbing system.

1.2 Inserting the Plumbing Test Ball

Once the plumbing test ball is prepared, it’s time to insert it into the pipe. If you are using an inflatable test ball, deflate it fully before insertion to ensure easier entry. Use a suitable insertion tool or extension rod to guide the test ball into the pipe until it reaches the desired location.

When inserting the test ball, it’s essential to take note of the correct orientation. The inflation valve or mechanical plug should be facing towards you so that it can be easily accessed for inflation or removal purposes when necessary.

For larger diameter pipes or longer lengths, it may be necessary to use multiple test balls to achieve an effective seal. In such cases, ensure that each test ball is properly inserted with sufficient spacing between them to guarantee a secure seal along the entire length of the pipe.

2. Inflating and Testing the Plumbing Test Ball

Once the plumbing test ball is correctly inserted into the pipe, it’s time to inflate the inflatable test balls or activate the mechanical seal for mechanical test balls. Follow the manufacturer’s instructions for inflating the test ball to the recommended pressure. It’s essential not to overinflate the test ball, as it can lead to damage or an ineffective seal.

After inflation, observe the test ball closely for any signs of leakage or deflation. If you notice any leaks or loss of pressure, it indicates a faulty seal or a defect in the test ball. In such cases, you will need to rectify the issue, either by adjusting the position of the test ball or replacing it altogether.

If you are performing a pressure test on the plumbing system, connect the necessary pressure gauge or monitoring equipment to the test ball to measure the pressure accurately. Ensure that the pressure remains stable and within the recommended range throughout the testing process.

2.1 Conducting the Plumbing Test

Once the plumbing test ball is securely inflated and in place, you can proceed with the plumbing test. This could involve testing the system for leaks, checking for blockages, or determining the overall integrity of the pipes.

If you are conducting a leak test, apply soapy water or a leak detection solution to the joints and connections. Look out for any bubbling or foaming, which indicates the presence of a leak. Additionally, visually inspect the pipes for any signs of water seepage or abnormal moisture.

For blockage testing, ensure that the plumbing test ball effectively blocks the pipe, preventing the flow of water or other substances downstream. Observe the pipes for any signs of a backup or overflow, indicating a blockage within the system.

2.2 Removing the Plumbing Test Ball

Once the plumbing test is complete, it’s time to remove the test ball from the pipe. Start by deflating the inflatable test ball using the inflation valve, following the manufacturer’s instructions. As the test ball deflates, it should become easier to remove.

For mechanical test balls, follow the specific instructions to release the mechanical seal or plug, allowing for the removal of the test ball from the pipe.

When removing the test ball, exercise caution to prevent any damages to the plumbing system or the test ball itself. Use the insertion tool or extension rod to guide the test ball out of the pipe slowly. Avoid any sudden movements or pulling, as it can cause unnecessary strain or accidents.

3. Safety Considerations and Precautions

When using a plumbing test ball, it’s essential to prioritize safety and follow certain precautions to avoid any injuries or damage to the plumbing system. Consider the following:

- Wear appropriate personal protective equipment (PPE) such as safety gloves and goggles.

- Ensure proper ventilation in the area where the plumbing test is being conducted.

- Take note of any applicable regulations or codes regarding plumbing testing in your area.

- Follow the manufacturer’s instructions for the specific plumbing test ball being used.

- Inspect the test ball for any defects or damages before use, and replace if necessary.

- Do not overinflate the test ball, as it can compromise the effectiveness and lead to damage.

- Be mindful of the pipe material and its ability to withstand pressure during testing.

By adhering to these safety considerations, you can ensure a safe and successful plumbing test.

4. Benefits of Using a Plumbing Test Ball

Using a plumbing test ball offers several benefits for both professional plumbers and homeowners tackling plumbing projects. These benefits include:

- Efficient testing: Plumbing test balls allow for quick and efficient testing of pipes, identifying any leaks, blockages, or integrity issues.

- Cost-effective: By pinpointing potential issues early on, plumbing test balls help prevent more extensive damage and costly repairs in the future.

- Temporary repairs: Mechanical test balls can provide a temporary solution for pipe repairs, allowing for proper isolation of damaged sections for further repairs or replacements.

- Convenience and versatility: Plumbing test balls are available in various sizes and types, making them suitable for a wide range of plumbing applications.

By utilizing a plumbing test ball effectively, you can benefit from these advantages and ensure the reliability and functionality of your plumbing system.

To conclude, using a plumbing test ball is a vital part of conducting plumbing tests, repairs, and installations. By selecting the appropriate size and type, properly preparing and inserting the test ball, conducting the necessary tests, and prioritizing safety, you can achieve accurate and reliable results. Remember to follow the manufacturer’s instructions and consult with professionals when needed to ensure the success of your plumbing project.

How To Use A Plumbing Test Ball?

A plumbing test ball is a useful tool for conducting pressure tests in plumbing systems. Here’s how to use it:

1. Choose the right size test ball for your pipe diameter. The test ball should fit snugly inside the pipe.

2. Deflate the test ball by releasing the air. This will make it easier to insert into the pipe.

3. Insert the deflated test ball into the pipe, making sure it is positioned correctly.

4. Use an air compressor to inflate the test ball until it completely seals the pipe. Make sure the pressure is within the recommended range.

5. Once the test ball is inflated, use a pressure gauge to monitor the pressure inside the pipe. Check for any leaks or pressure drops.

6. After completing the pressure test, deflate the test ball and remove it from the pipe.

Using a plumbing test ball correctly ensures accurate pressure testing and helps identify any potential issues in the plumbing system.

Key Takeaways – How To Use A Plumbing Test Ball

- A plumbing test ball is a tool used to block the flow of liquids or gases in plumbing systems.

- Before using a plumbing test ball, ensure that it is the correct size for the pipe you are working on.

- Insert the deflated plumbing test ball into the pipe and use an inflation device to inflate it.

- The inflated plumbing test ball creates a seal, preventing the flow of liquids or gases.

- To release the test ball, simply deflate it using the inflation device and remove it from the pipe.

Frequently Asked Questions

Plumbing test balls are essential tools for testing and sealing pipes during plumbing projects. If you’re unsure about how to use a plumbing test ball, we’ve got you covered. Here are some frequently asked questions about using a plumbing test ball:

1. What is a plumbing test ball?

A plumbing test ball is a device used to test the integrity of pipes and to block the flow of water or air. It is typically made of a flexible material, such as rubber or silicone, and comes in different sizes to fit various pipe diameters.

When inflated, the test ball creates a seal inside the pipe, allowing for pressure testing or blocking the flow of water or air during maintenance or repairs.

2. How do I choose the right size of a plumbing test ball?

Choosing the right size of a plumbing test ball is crucial for a proper fit and effective sealing. To determine the correct size, measure the inside diameter of the pipe using a measuring tape or caliper.

Select a test ball that matches the measured diameter or slightly smaller. It should fit snugly inside the pipe when inflated. Using a test ball of the wrong size may result in an inadequate seal and compromised testing or blocking.

3. How do I inflate a plumbing test ball?

To inflate a plumbing test ball, you will need an air compressor or a hand pump with a suitable nozzle attachment. Follow these steps:

1. Ensure the test ball’s valve is closed.

2. Attach the pump or compressor nozzle securely to the valve.

3. Gradually inflate the test ball, monitoring its size to prevent overinflation. Stop inflating once it reaches the appropriate size for the pipe.

4. How do I insert a plumbing test ball into a pipe?

Inserting a plumbing test ball into a pipe requires careful handling to avoid damaging the ball or the pipe. Follow these steps:

1. Deflate the test ball completely.

2. Lubricate the outer surface of the deflated ball and the inner surface of the pipe with a suitable lubricant.

3. Gently push the deflated test ball into the pipe, ensuring it does not catch on any obstructions.

4. Once the test ball is inside the pipe, carefully inflate it to create a seal.

5. How do I remove a plumbing test ball from a pipe?

Removing a plumbing test ball from a pipe is a simple process if done correctly. Follow these steps:

1. Deflate the test ball using the release valve.

2. Use a suitable tool, such as pliers or a hook, to grip onto the deflated test ball.

3. Slowly and carefully pull the deflated test ball out of the pipe, ensuring it does not get stuck or damage the pipe.

These are some of the commonly asked questions about using a plumbing test ball. By following the instructions provided, you should be able to use a plumbing test ball effectively and safely during your plumbing projects.

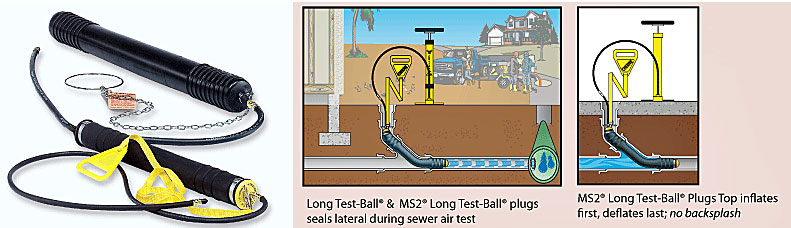

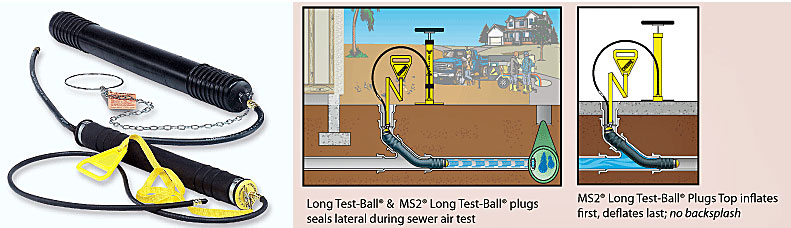

Pressure testing bathroom remodeling with 4\” Cherne long test-ball plug. #plumbing #remodel #diy

In conclusion, using a plumbing test ball is a straightforward process that requires a few simple steps. First, ensure that the test ball is properly inflated and has the correct size for the plumbing pipe. Next, insert the test ball into the pipe and position it at the desired location. Then, use a pressure gauge to determine the level of air pressure needed to achieve a proper seal. Inflate the test ball to the recommended pressure and check for any signs of leakage. Finally, once the test is completed, deflate the test ball and remove it from the pipe.

Remember to follow the manufacturer’s instructions when using a plumbing test ball and always prioritize safety. By using a test ball correctly, you can effectively block the flow of water or air in pipes for various plumbing applications, such as testing for leaks or conducting maintenance work. With these simple steps, you can confidently use a plumbing test ball and ensure the efficient and effective functioning of your plumbing system.