A wye in plumbing is a type of fitting that is used to connect three pipes together at a 45-degree angle. It is commonly used in plumbing systems to redirect the flow of water or other fluids. The unique design of the wye allows for smooth and efficient flow without creating excessive turbulence or pressure loss. This makes it an essential component in many plumbing applications.

The history of the wye fitting dates back to ancient plumbing systems, where it was used to join pipes in intricate water distribution networks. Today, wye fittings are made from various materials such as PVC, copper, or cast iron, depending on the specific requirements of the plumbing system. According to industry statistics, wye fittings are among the most commonly used fittings in residential, commercial, and industrial plumbing projects. They provide a reliable and cost-effective solution for connecting pipes and ensuring proper flow in plumbing systems.

A wye in plumbing is a type of pipe fitting that is shaped like the letter “Y.” It is used to connect three pipes together at different angles, allowing the flow of water or other fluids. The wye fitting has two branches that are angled in the same direction and one perpendicular branch. This design helps to divert the flow of fluids in the desired direction and is commonly used in plumbing systems to connect fixtures like toilets, sinks, and showers. It provides a reliable and efficient way to distribute water throughout a building.

Understanding the Wye in Plumbing

The wye fitting is an important component in plumbing systems, commonly used to connect three pipes together. Its unique shape, resembling the letter “Y,” allows for the redirection or division of fluid flow. Whether you’re a professional plumber or a homeowner, understanding the wye fitting and its applications is crucial for maintaining efficient plumbing systems. In this article, we will explore the various aspects of wye fittings in plumbing, including their design, uses, and installation.

Design and Functionality of Wye Fittings

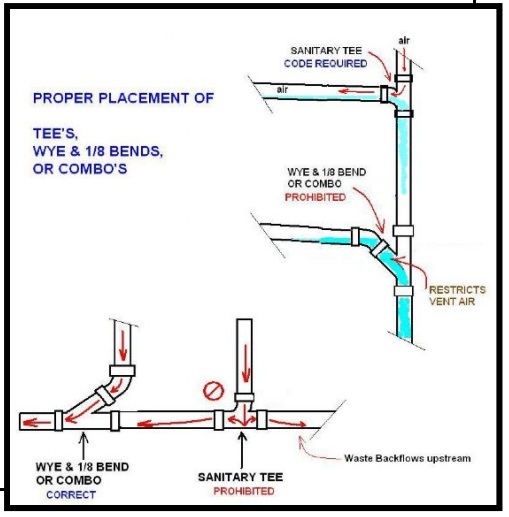

Wye fittings, also known as Y fittings, are designed with a Y-shaped junction that allows for the joining of three pipes. They typically have three openings of equal diameter, with one main inlet and two outlets at an angle of 45 degrees. The main difference between a wye fitting and a tee fitting is that the outlets in a wye fitting are angled, while the outlets in a tee fitting are perpendicular.

The purpose of a wye fitting is to divert or split the flow of liquids or gases. When fluid enters the main inlet of a wye fitting, it can be directed towards one outlet or split between both outlets, depending on the specific plumbing configuration. This makes wye fittings ideal for applications where flow division or redirection is necessary, such as in drainage systems, vent pipes, or irrigation systems.

Wye fittings are typically made from durable materials such as PVC, ABS, or cast iron. These materials provide corrosion resistance and ensure the longevity of the plumbing system. The design and materials used in wye fittings allow for smooth and efficient flow of fluids, reducing the risk of clogs or blockages.

Common Uses of Wye Fittings

Wye fittings find a wide range of applications in plumbing systems. Here are some common uses:

- Drainage Systems: Wye fittings are commonly used in drainage systems to redirect or split the flow of wastewater. They help to ensure proper drainage and prevent backups or clogs.

- Vent Pipes: In plumbing systems, vent pipes are essential for releasing sewer gases and maintaining proper air pressure. Wye fittings are used to connect vent pipes and redirect the airflow.

- Irrigation Systems: Wye fittings are used in irrigation systems to split the flow of water to different areas, ensuring even distribution for efficient watering.

- Branch Lines: Wye fittings can be used to connect branch lines to the main supply lines, allowing for the flow of fluids in multiple directions.

Installation of Wye Fittings

Proper installation of wye fittings is crucial for a leak-free and efficient plumbing system. Here are some essential tips for installing wye fittings:

- Ensure correct sizing: It is important to select wye fittings with the right diameter to match the pipes being connected. Proper sizing will ensure a tight and secure fit.

- Prepare the pipes: Clean and prepare the pipe ends before attaching the wye fitting. Remove any burrs or debris that may affect the tightness of the connection.

- Apply adhesive: If using PVC or ABS wye fittings, apply a suitable adhesive to secure the joints. Follow the manufacturer’s instructions for the adhesive application.

- Tighten connections: Use appropriate tools or wrenches to tighten the connections. However, avoid overtightening, as it can lead to damage or leaks.

- Check for leaks: After installation, test the system for any leaks or drips. Make sure all connections are secure and properly sealed.

The Advantages of Using Wye Fittings

Wye fittings offer several advantages that make them a popular choice in plumbing systems:

- Flow division: The unique design of wye fittings allows for the flow of fluids to be redirected or split between multiple pipes, providing flexibility in plumbing configurations.

- Reduced clogs: The smooth interior of wye fittings minimizes the risk of debris buildup and clogs, ensuring a continuous flow of fluids.

- Durability: Wye fittings are typically made from durable materials that can withstand the demands of plumbing systems. They are resistant to corrosion and can withstand high pressures.

- Efficiency: Wye fittings ensure efficient flow distribution, reducing pressure drops and maintaining optimal system performance.

Common Alternatives to Wye Fittings

While wye fittings are versatile and widely used, there are alternatives available for specific plumbing needs:

- Tee fittings: Tee fittings are commonly used when a perpendicular connection is required. They are ideal for branching off a main supply line.

- Elbows: Elbows are used to change the direction of piping, typically at a 90-degree angle. They are not designed for flow division.

- Couplings: Couplings are used to join two pipes of the same diameter in a straight line. They do not offer the same flow diversion capabilities as wye fittings.

Exploring the Versatility of Wye Fittings

Wye fittings are an essential component in plumbing systems, providing the means to redirect or split the flow of fluids. Whether it’s in drainage systems, vent pipes, or irrigation systems, wye fittings offer versatility and efficiency. By understanding their design, uses, and installation, you can ensure the proper functioning of your plumbing system. Consider the advantages of wye fittings and their alternatives for your specific plumbing needs.

Understanding the Function of a Wye in Plumbing

In the realm of plumbing, a wye is a specific fitting that plays a crucial role in directing the flow of liquids or gases in a pipe system. It is commonly used in drainage and ventilation systems. The wye fitting resembles the letter “Y,” hence its name.

The primary function of a wye is to join multiple pipes at a junction, allowing fluid or air to flow in two different directions. It is particularly useful to connect a horizontal pipe to a vertical pipe, commonly seen in plumbing fixtures such as toilets and sinks. The angled design of a wye fitting ensures a smooth and efficient flow without causing clogs or blockages.

Wyes are typically made of durable materials such as PVC, copper, or cast iron, depending on the specific application and the plumbing code requirements. They come in various sizes to accommodate different pipe dimensions. It is crucial to select the correct size and material to ensure the fitting’s compatibility with the plumbing system.

The proper installation of wye fittings is essential for the overall functionality and efficiency of a plumbing system. It is crucial to follow the appropriate building codes and guidelines to ensure a leak-free and reliable pipe network.

Key Takeaways – What Is A Wye In Plumbing?

- A wye is a type of plumbing fitting used to connect two drain pipes in a T-shaped configuration.

- It allows for the diversion of wastewater from one pipe to another, while also allowing for proper drainage.

- Wyes are commonly used in plumbing systems, especially in residential and commercial buildings.

- They are typically made of durable materials like PVC or cast iron to ensure long-lasting performance.

- Proper installation and maintenance of wye fittings are crucial to ensure efficient and leak-free drainage systems.

Frequently Asked Questions

Plumbing fittings and components can be complex, and one term often used is “wye”. In plumbing, a wye is a type of fitting that is commonly used to divert or combine the flow of wastewater or water. It is shaped like the letter “Y” and is designed to connect pipes or tubes at a 45-degree angle. If you’re not familiar with what a wye is and how it is used in plumbing systems, we have answered some frequently asked questions below.

1. How is a wye different from other plumbing fittings?

A wye is a specific type of plumbing fitting that has a “Y” shape. It differs from other fittings like tees, elbows, or couplings in terms of its design and purpose. While an elbow fitting changes the direction of a flow by 90 degrees, a wye fitting diverts the flow at a 45-degree angle. It is commonly used to connect an inclined branch pipe to a horizontal pipe, allowing the flow to be directed in different directions.

In addition, a wye fitting is also different from a tee fitting. A tee fitting has an additional outlet on the same plane, forming a “T” shape, while a wye fitting has only one outlet on the same plane as the inlet, forming a “Y” shape. This makes the wye fitting ideal for diverting the flow into two separate directions.

2. What are the main uses of a wye in plumbing?

A wye fitting is used in various plumbing applications. Some of the main uses include:

1. Diverting wastewater: In drain and sewer systems, a wye fitting is commonly used to combine the flow from multiple branch pipes into a main sewer line. It allows the wastewater to be diverted into the main line while maintaining proper flow and preventing blockages.

2. Venting systems: A wye fitting is also used in venting systems to connect fixture vents to the main vent stack. It allows air to enter the plumbing system, preventing suction and promoting proper drainage.

3. Irrigation systems: In irrigation systems, a wye fitting is used to split the water flow into multiple directions, allowing water to reach different areas or zones. This helps in efficient watering of plants and landscapes.

3. What materials are wye fittings made of?

Wye fittings are typically made of different materials, depending on the specific plumbing application and requirements. Some common materials used for wye fittings include:

1. PVC (Polyvinyl Chloride): PVC wye fittings are commonly used in residential and commercial plumbing systems due to their durability, affordability, and resistance to corrosion.

2. ABS (Acrylonitrile Butadiene Styrene): ABS wye fittings are commonly used in drainage and sewer systems. They are known for their impact resistance and suitability for above-ground applications.

3. Cast iron: Cast iron wye fittings are commonly used in older plumbing systems or in applications that require high strength and durability.

It is important to select the appropriate material for wye fittings based on the specific plumbing requirements, code compliance, and the type of fluid being transported.

4. How are wye fittings installed?

Installing a wye fitting in a plumbing system involves the following steps:

1. Measure and mark the pipes: Measure and mark the sections of the pipes where the wye fitting will be installed. Ensure accurate measurements and proper alignment.

2. Cut the pipes: Use a pipe cutter or saw to cut the pipes at the marked locations. Ensure clean, square cuts to achieve a tight fit with the wye fitting.

3. Apply primer and cement: Clean the cut ends of the pipes and apply a primer that prepares the surface for proper bonding. Apply a layer of PVC cement to both the pipes and the wye fitting sockets.

4. Insert the pipes into the wye fitting: Insert the cut ends of the pipes into the corresponding sockets of the wye fitting. Ensure a secure and tight fit.

5. Allow the cement to dry: Allow sufficient time for the cement to dry and form a strong bond. Follow the manufacturer’s instructions for drying time.

6. Test for leaks: Once the cement has dried, test the installed wye fitting and pipes for any leaks. Run water through the system and inspect for any signs of leakage.

5. Can a wye fitting be used in any orientation?

No, a wye fitting should be installed in a specific orientation to ensure proper flow and functionality. The orientation of a wye fitting is crucial because it determines the direction of flow and how the flow is split.

It is important to read the manufacturer’s instructions and follow local plumbing codes when installing a wye fitting. The inlet of the wye fitting should always be at the top, and the outlets should be at the same plane as the inlet. This ensures proper drainage and prevents any reverse flow or backflow in the plumbing system.

Using a wye fitting in the wrong orientation can lead to drainage issues, blockages, and other plumbing problems. Always consult a professional plumber or refer to the manufacturer’s guidelines for proper installation.

Where to use wyes, tees, and different types of elbows.(2021)

To wrap up, a wye in plumbing refers to a specific type of fitting that is used to connect three pipes together. It has a Y-shaped design, with one inlet and two outlets. The main purpose of a wye is to allow the flow of water or other fluids in different directions, thereby facilitating efficient plumbing systems.

In addition to its functionality, wyes are commonly used in plumbing systems because they are easy to install, durable, and cost-effective. They are typically made of materials such as PVC or cast iron, which ensures their longevity and resistance to corrosion. Wyes play a crucial role in ensuring the smooth and effective flow of water or other liquids through a plumbing system.